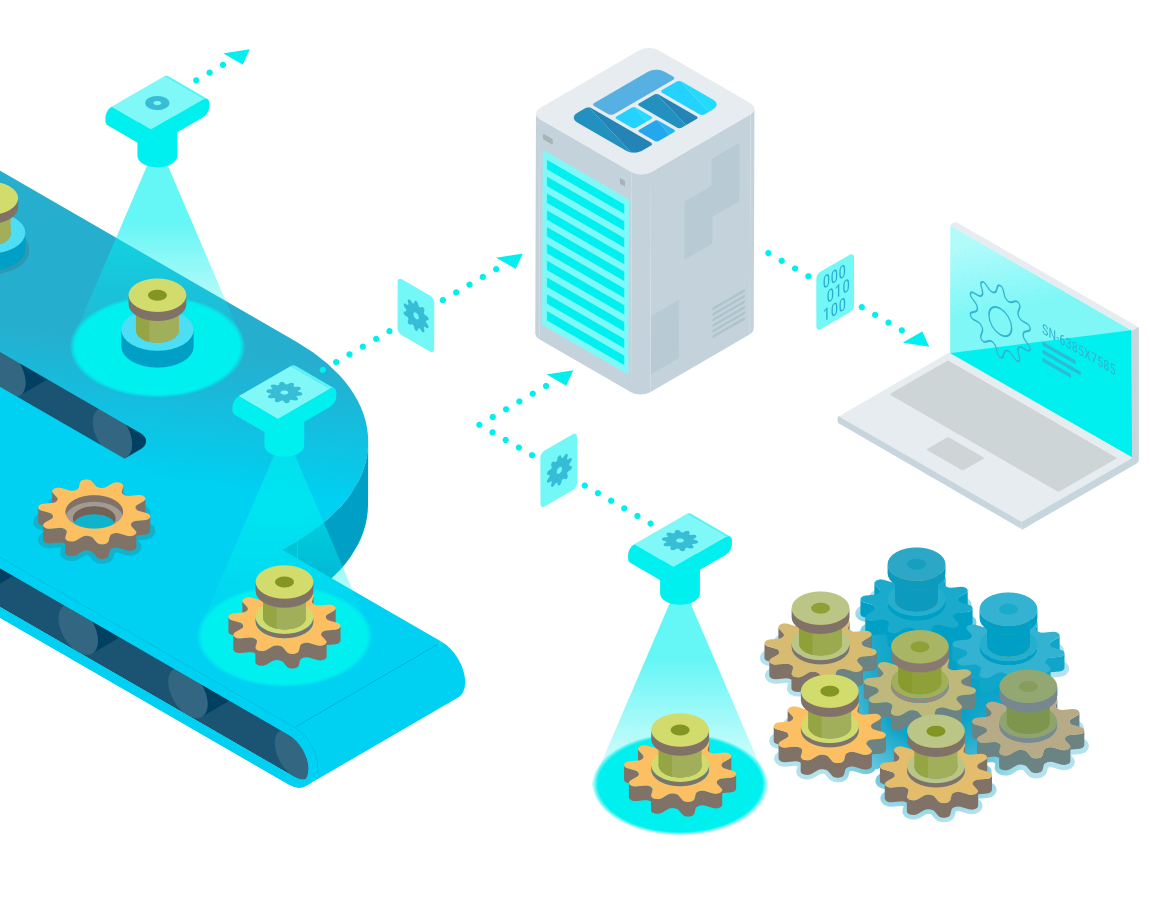

Basic principle

The surface of each component is photographed as early as possible in the production process, the fingerprint is generated and stored in a database together with the serial number of the part. From this point onwards, any production, measurement and quality data can be linked to the serial number - either in the Detagto software or in the company's own MES, ERP or QMS system. To do this, the component simply needs to be photographed again and identified using its fingerprint. Just as with humans, several fingerprints can be taken initially, but later only one of these surface areas is sufficient to uniquely identify the workpiece.

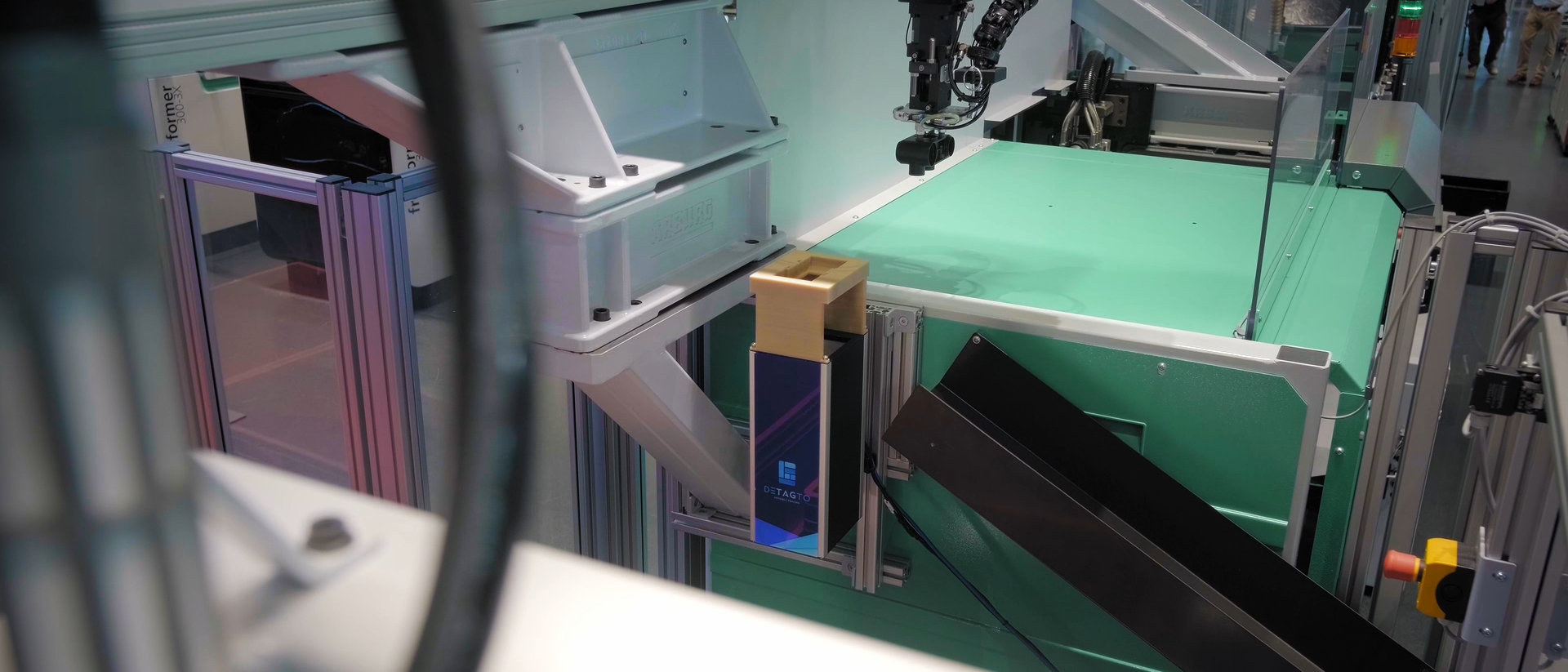

Inline system

Detagto's traceability solution only requires a standard industrial camera. Thanks to the compact design and simplicity of the hardware, the camera systems can be easily integrated into existing production lines. The image material is processed either on a computer on premise, on a server in a data center or in the cloud. The digital fingerprint is generated from the image of the part and stored in the database.

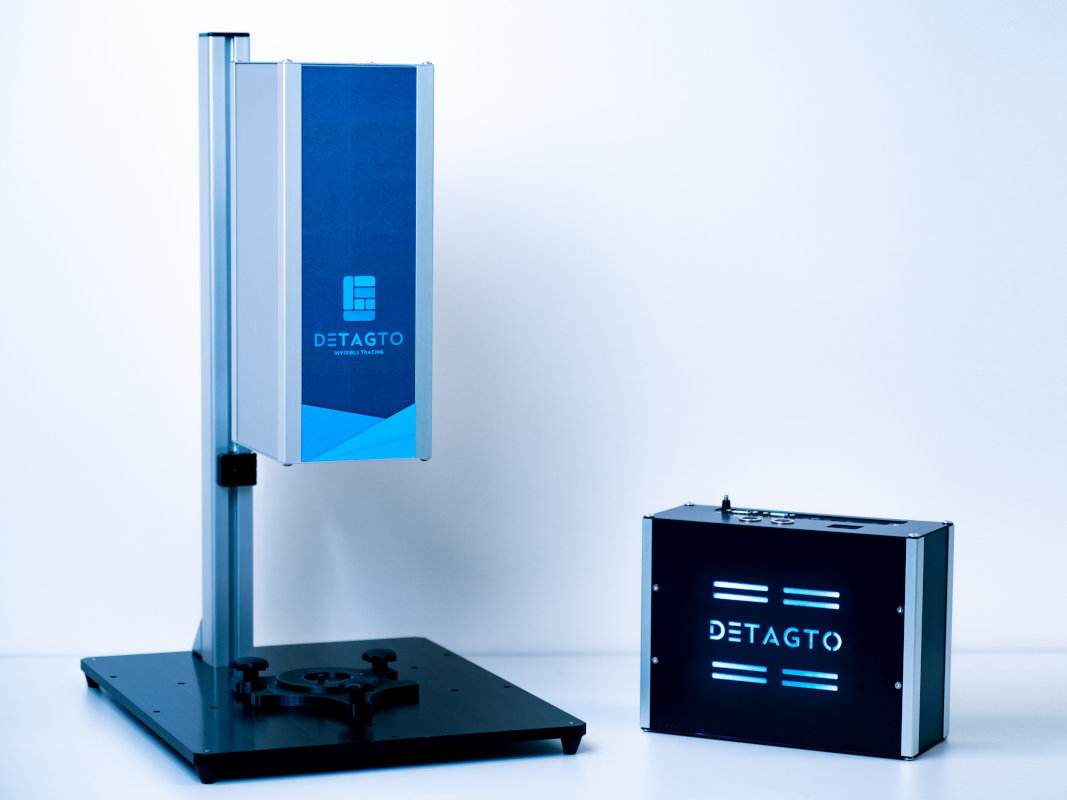

Standalone system

In many situations, a manually controlled system is required rather than a fully integrated, automated solution - for example, if random samples are regularly taken and analyzed as part of quality assurance or to inspect product rejects and reclaimed parts. Detagto offers a cost-efficient standalone system for this purpose, which is ready to use immediately and can be used for various parts and products.

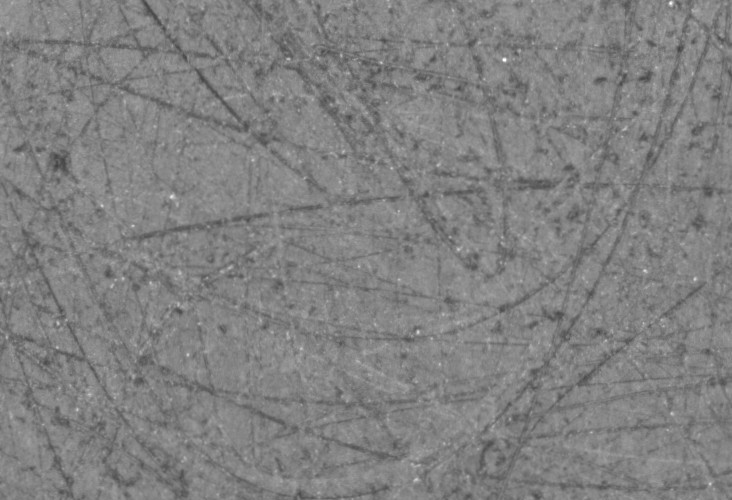

Robust against surface alterations

The algorithm for generating the fingerprints from the images is able to differentiate between relevant and irrelevant surface patterns. Hence, surface changes such as scratches or smudges only have a minor effect on the identification. This makes the process very robust.

Powerful interfaces

OPC UA

Many systems already have integrated OPC UA servers. The IRIS server can be connected directly to such an OPC UA server in order to trigger actions or transfer data.

REST-API

Various devices and modern software services can be connected to the IRIS server via HTTP using the REST API. This makes it easy to connect to MES or ERP systems, for example.

File crawler

If your system stores structured files (e.g. XML) in a directory, our system can monitor this and automatically link this data to the fingerprints.

Kontakt

Do you still have questions about how our Tagless Traceability works? Then get in touch with us! We will be happy to answer all your questions.